Essex Jaw Couplings

MOQ : 1 , , Piece

Essex Jaw Couplings Specification

- Head Code

- Round

- Material

- Steel

- Structure

- Jaw/Spider

- Color

- Black

- Application

- Industrial

- Surface Treatment

- Powder Coated

- Technique

- Casting

- Shape

- Round

Essex Jaw Couplings Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 5000 Pieces Pieces Per Day

- Delivery Time

- 3-30 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Western Europe, Australia, South America, Middle East, Africa, Asia, Central America, Eastern Europe, North America

- Main Domestic Market

- All India

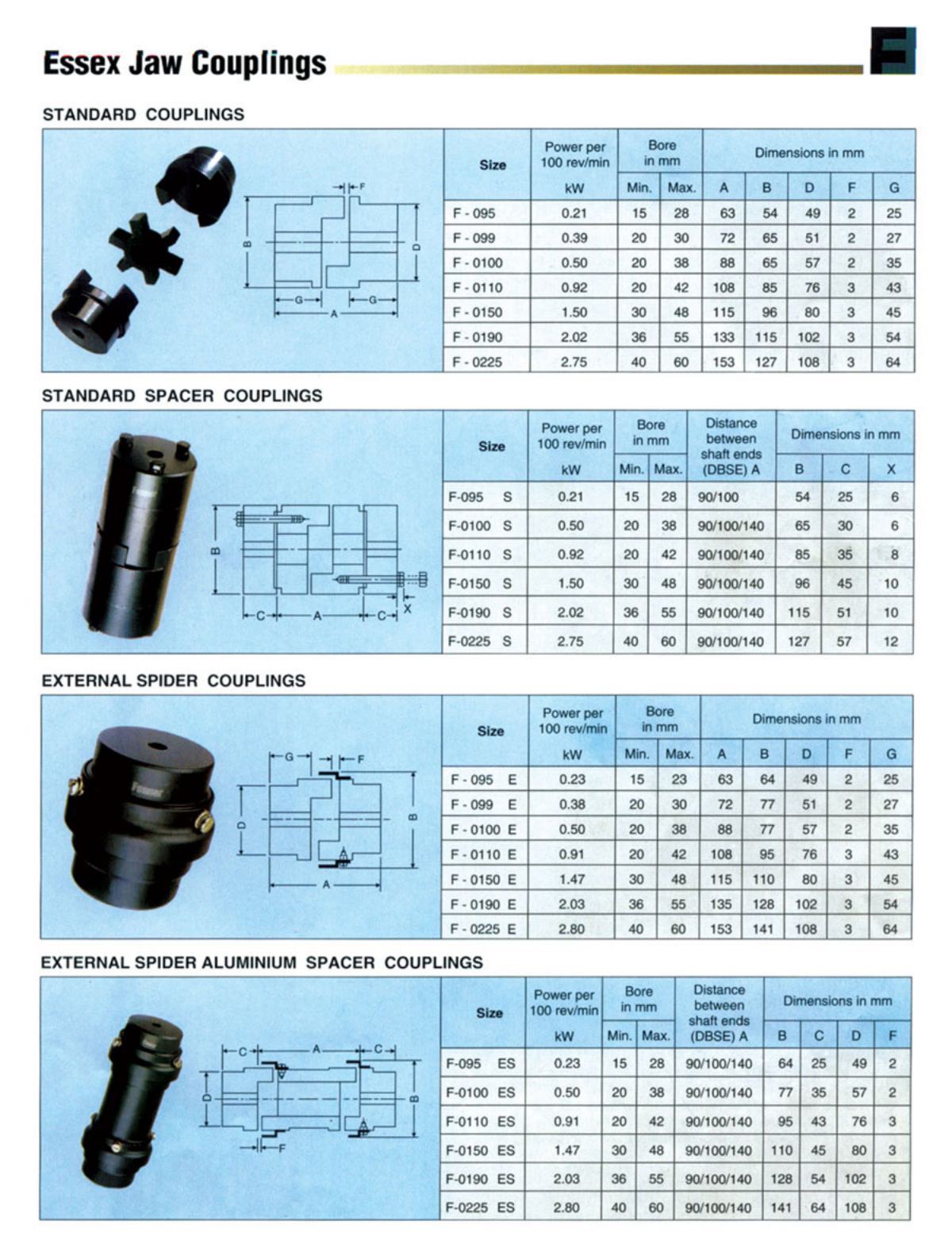

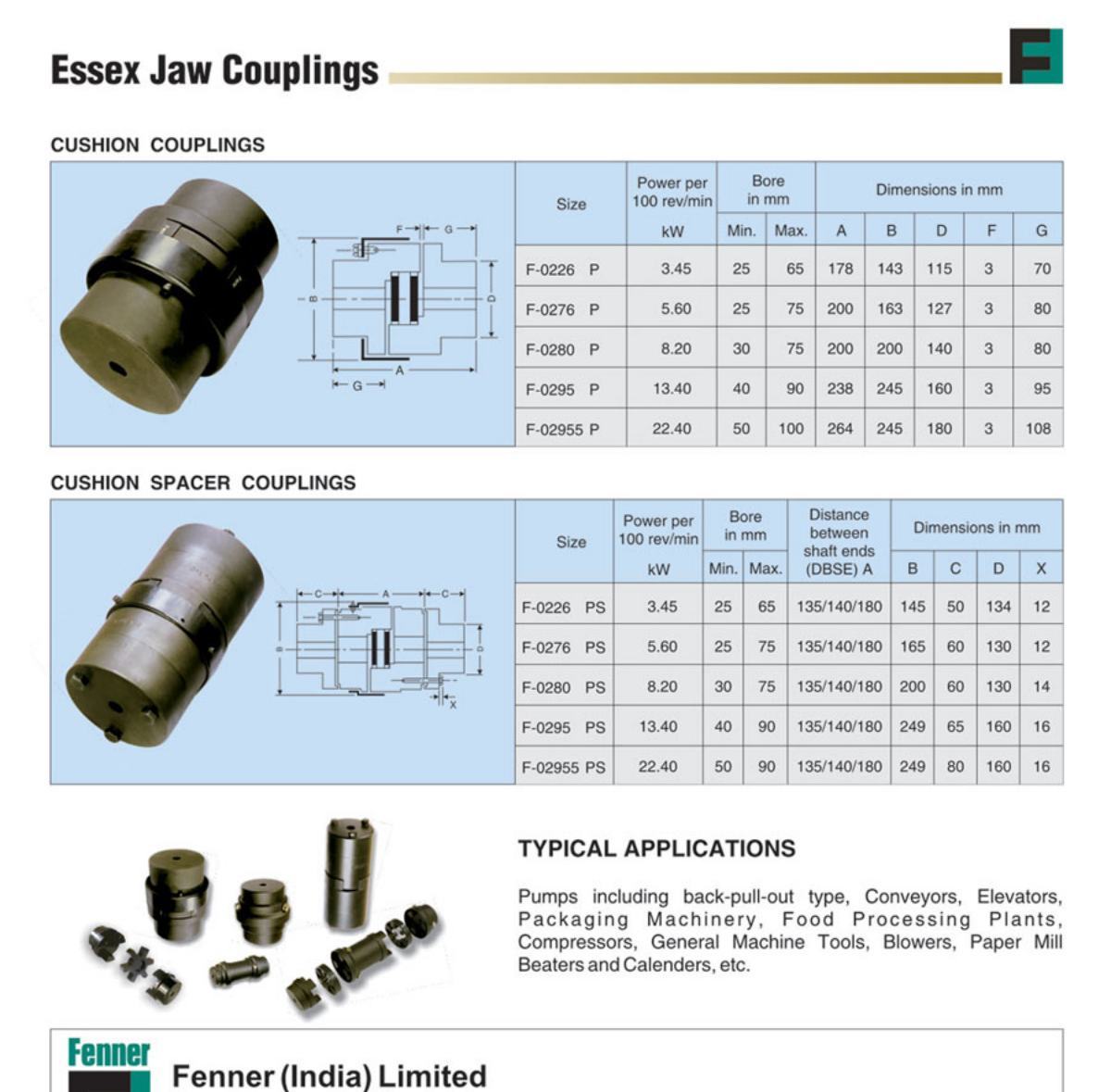

About Essex Jaw Couplings

Specification :

- Simple construction, quick easy installation, no special tools required.

- Flexible insert caters for incidental angular, parallel and axial misalignment.

- Absorbs shock loads and damps small amplitude vibrations.

- Insert design presets correct distance between hubs, using raised pads on each leg of the insert.

- Available in a range of stock bore sizes. Can also be supplied with finished bore and key way.

- Unaffected by moisture, grease and oils including non-aromatic and non-ketone solvents and temperatures within the range -40C to +100C.

- Spacer coupling with spacer size depending upon the distance between two shaft ends (DBSE).

Features

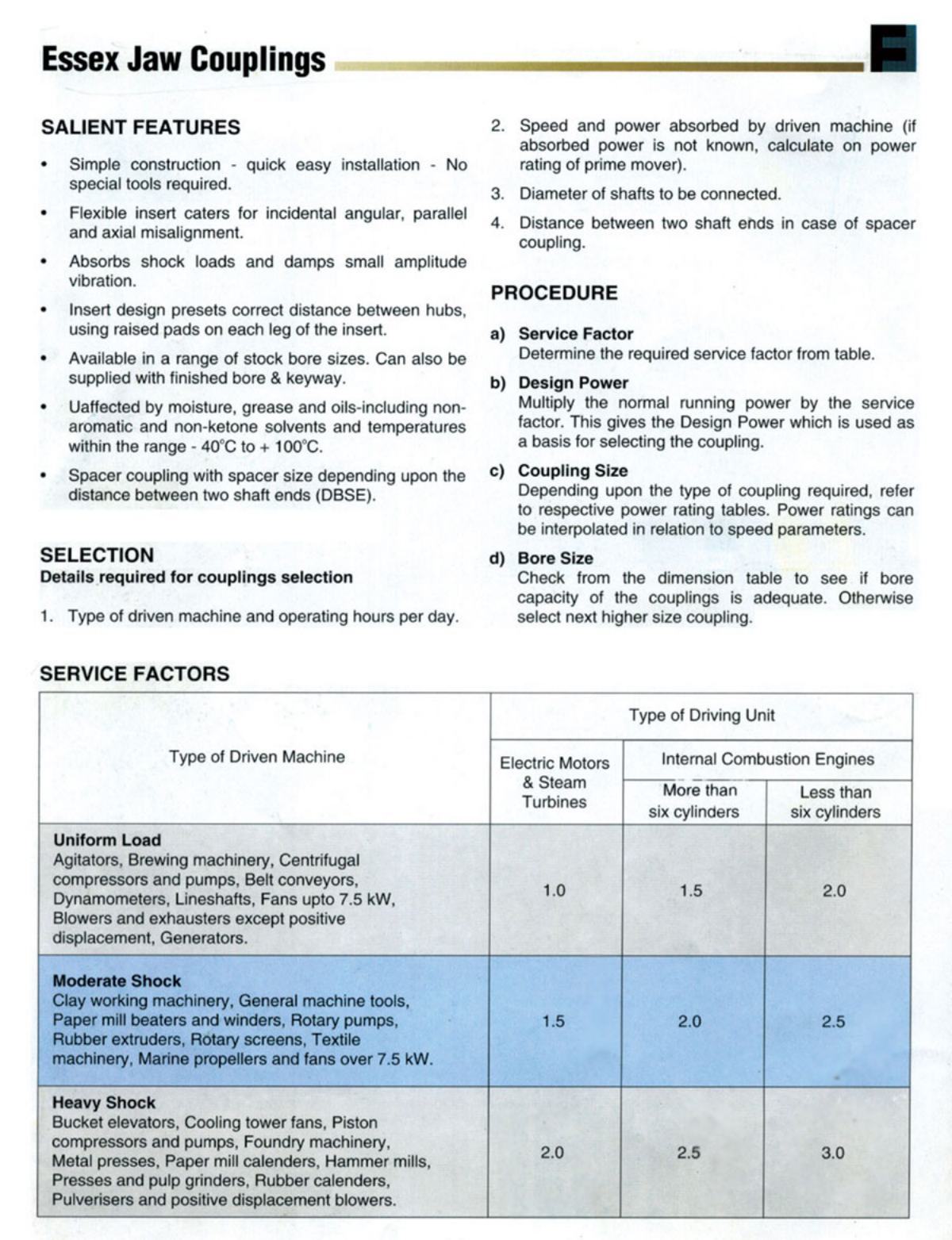

Design Power

Multiply the normal running power by the service factor. This gives the design power which is used as a basis for selecting the coupling

Coupling Size

Depending upon the type of coupling required, refer to respective power rating table, power rating cans be interpolation in relation to speed parameters.

FAQs of Essex Jaw Couplings:

Q: What material is used to manufacture Essex Jaw Couplings?

A: Essex Jaw Couplings are manufactured using steel.Q: What is the surface treatment applied to Essex Jaw Couplings?

A: The surface of Essex Jaw Couplings is powder coated.Q: What technique is used to produce Essex Jaw Couplings?

A: Essex Jaw Couplings are made using the casting technique.Q: What is the structure of the Essex Jaw Couplings?

A: The Essex Jaw Couplings have a jaw/spider structure.Q: What is the primary application of Essex Jaw Couplings?

A: Essex Jaw Couplings are primarily used for industrial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Jaw Couplings Category

Flexible Jaw Couplings

Minimum Order Quantity : 1 , , Piece

Surface Treatment : Polishing

Material : Steel

Application : Industrial

Technique : Casting

Structure : Jaw/Spider

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS