HRC Couplings

HRC Couplings Specification

- Head Code

- Round

- Material

- Steel

- Structure

- Jaw/Spider

- Color

- Black

- Application

- Industrial

- Surface Treatment

- Powder Coated

- Shape

- Round

HRC Couplings Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 5000 Pieces Pieces Per Day

- Delivery Time

- 3-30 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Central America, Africa, Middle East, South America, Asia

- Main Domestic Market

- All India

About HRC Couplings

Specification :

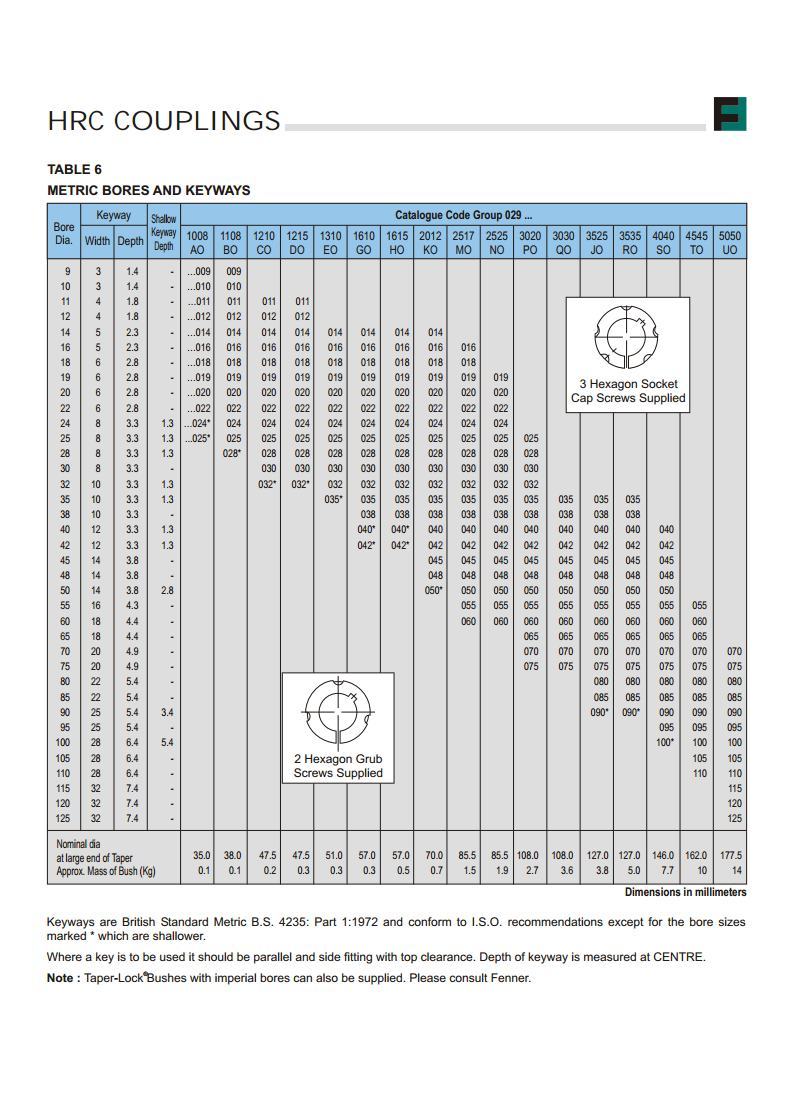

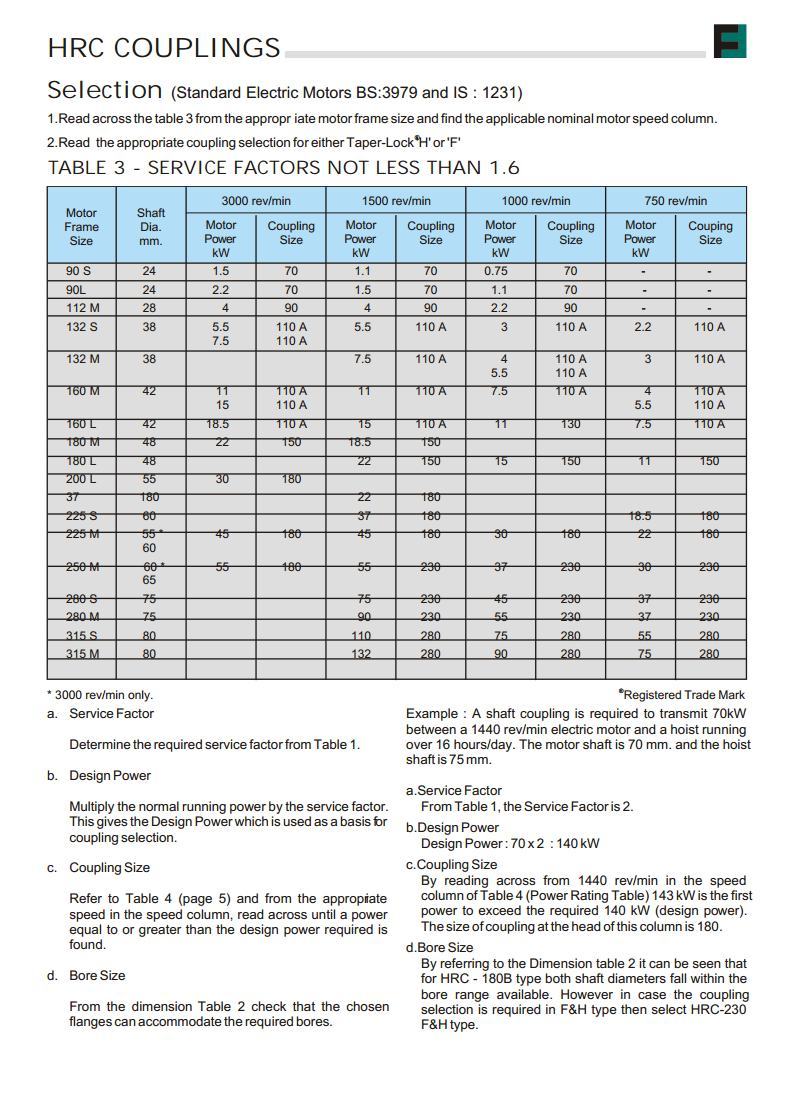

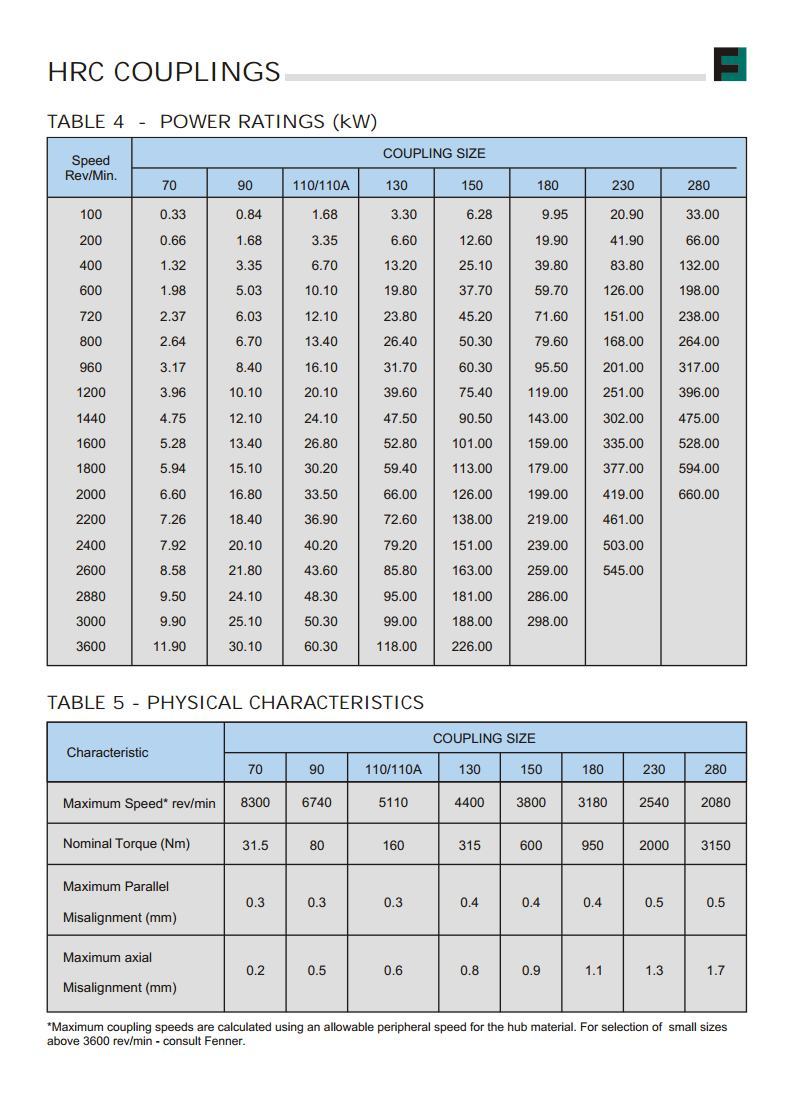

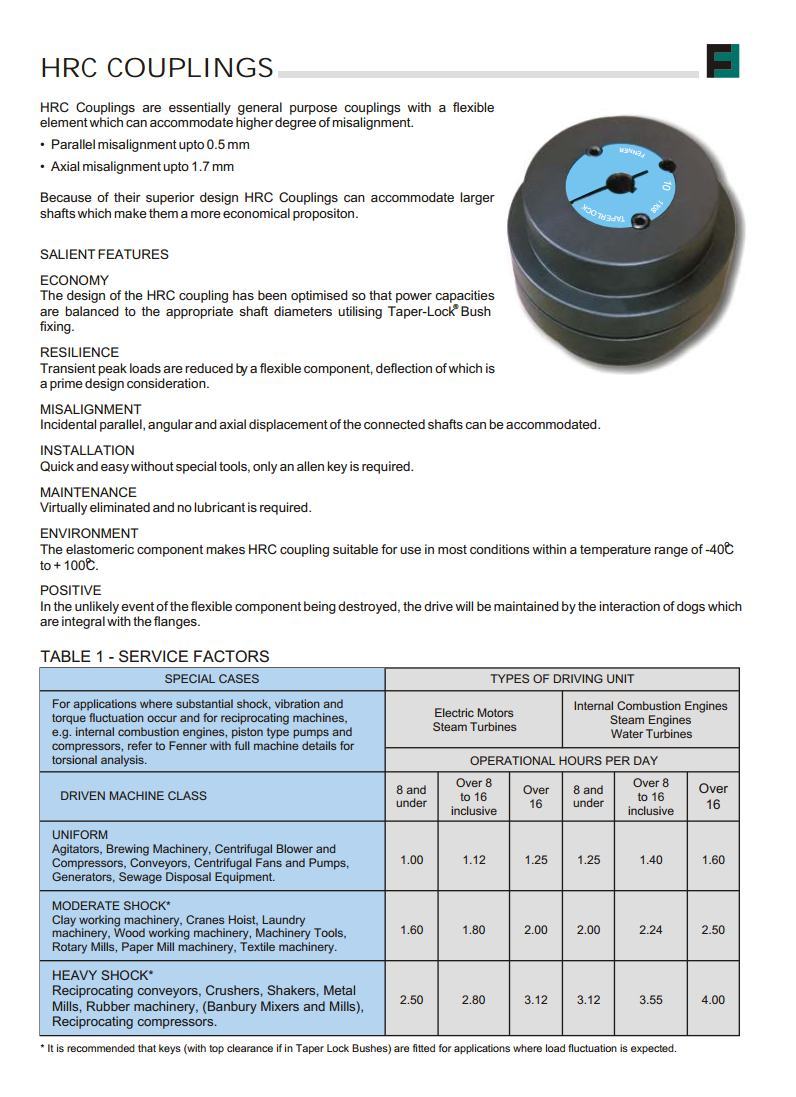

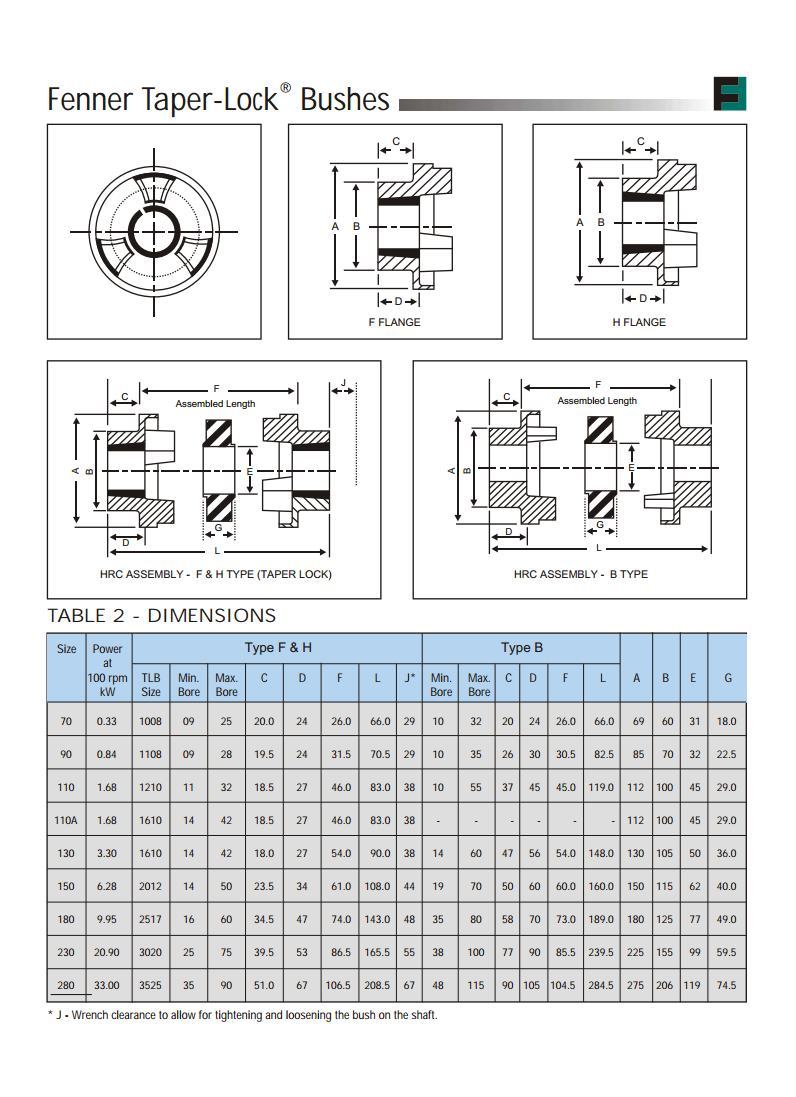

HRC Couplings are essentially general purpose couplings with a flexible element which can accommodate higher degree of misalignment. Parallel misalignment upto 0.5 mm. Axial misalignment upto 1.7 mm.

Because of their superior design HRC Couplings can accommodate larger shafts which make them a more economical propositon.

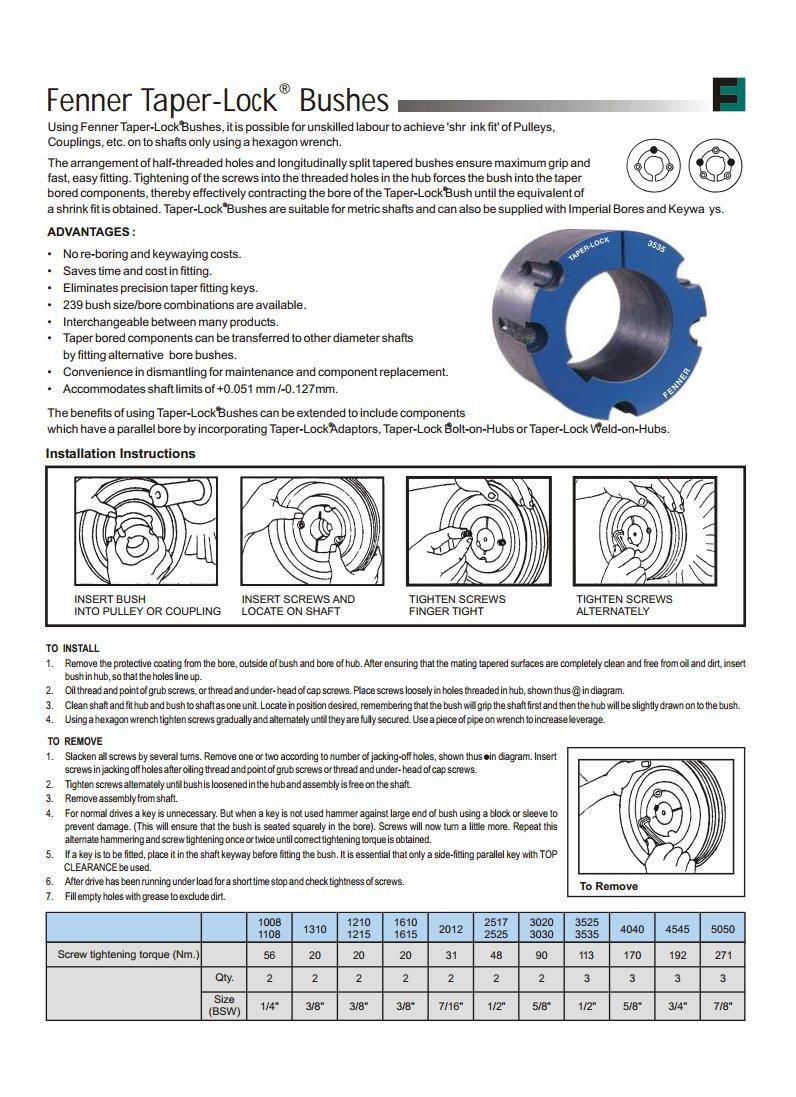

- SALIENT FEATURES: The design of the HRC coupling has been optimised so that power capacities are balanced to the appropriate shaft diameters utilising Taper-Lock Bush fixing.

- RESILIENCE: Transient peak loads are reduced by a flexible component, deflection of which is a prime design consideration.

- MISALIGNMENT: Incidental parallel, angular and axial displacement of the connected shafts can be accommodated.

- INSTALLATION: Quick and easy without special tools, only an allen key is required.

- MAINTENANCE: Virtually eliminated and no lubricant is required.

- ENVIRONMENT: The elastomeric component makes HRC coupling suitable for use in most conditions within a temper ature range of -40C O to + 100C.

- POSITIVE: In the unlikely event of the flexible component being destroyed, the drive will be maintained by the interaction of dogs which are integral with the flanges

- Temperatures from: 400 C to 1000 degree

- Power rating: 0.33 kW to 33 kW at 100 rpm

FAQs of HRC Couplings:

Q: What is the structure of HRC Couplings?

A: The structure of HRC Couplings is Jaw/Spider.Q: What is the shape of the HRC Couplings?

A: The shape of the HRC Couplings is round.Q: What material are HRC Couplings made of?

A: HRC Couplings are made of steel.Q: What surface treatment is applied to HRC Couplings?

A: HRC Couplings are powder coated for surface treatment.Q: What is the primary application of HRC Couplings?

A: HRC Couplings are primarily used in industrial applications.Q: What color are HRC Couplings available in?

A: HRC Couplings are available in black color.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Couplings Category

Gear Couplings

Minimum Order Quantity : 1 Piece

Shape : Round

Material : Steel

Structure : Gear

Technique : Casting

Application : Industrial

Fenner Resilient Spring Grid Couplings

Minimum Order Quantity : 1 Piece

Shape : Round

Material : Steel

Structure : Jaw/Spider

Technique : Casting

Application : Industrial

Rubber Coupling

Minimum Order Quantity : 1 Piece

Shape : Round

Material : Steel

Structure : Jaw/Spider

Technique : Casting

Application : Industrial

Bush Type Flexible Couplings

Minimum Order Quantity : 1 Piece

Shape : Round

Material : Steel

Structure : Jaw/Spider

Technique : Casting

Application : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free