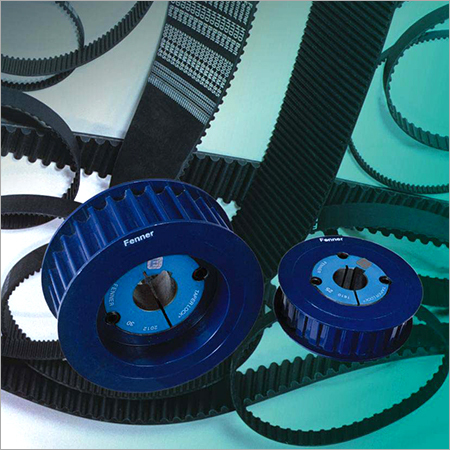

Synchronous Belts

Synchronous Belts Specification

- Usage

- Industrial

- Width

- 10-100 Millimeter (mm)

- Color

- Black

- Material

- Rubber

- Structure

- Belt

- Belt Conveyor

- Flat Belt

- Resistant Feature

- Oil Resistant

Synchronous Belts Trade Information

- Minimum Order Quantity

- 10 Meters

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 5000 Meters Per Day

- Delivery Time

- 3-30 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Western Europe, Eastern Europe, Central America, Africa, Middle East, South America, Australia, Asia, North America

- Main Domestic Market

- All India

About Synchronous Belts

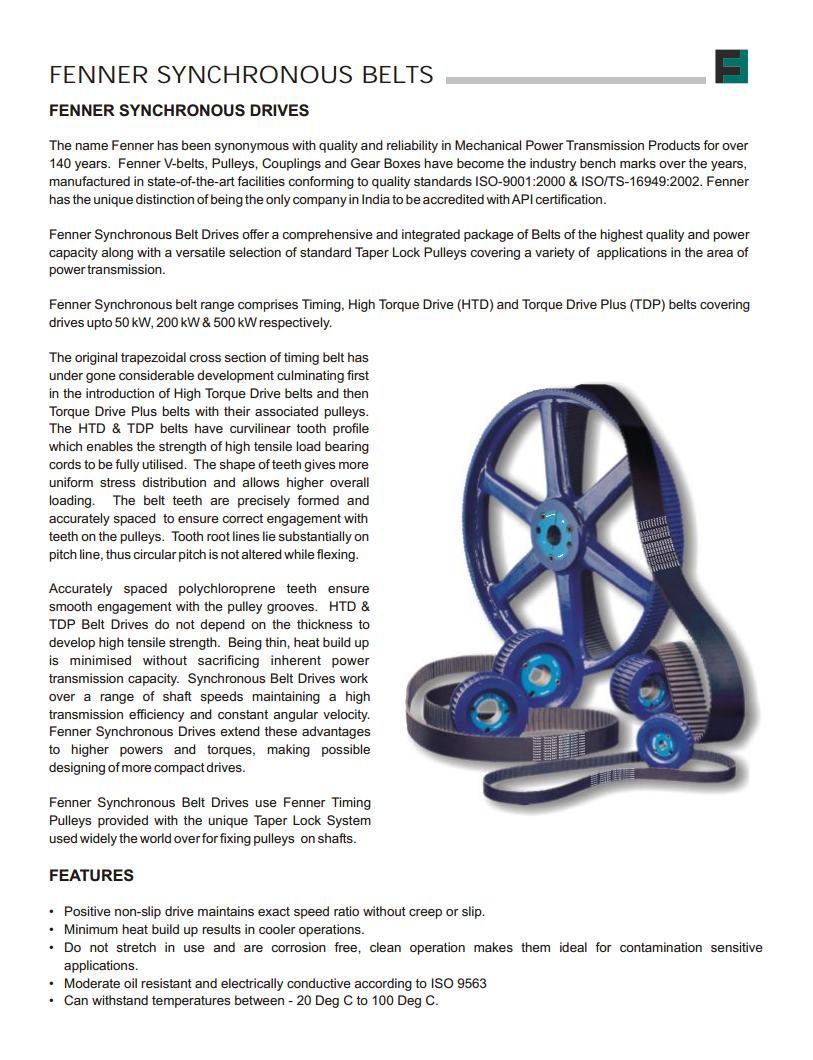

Capitalizing on our state-of-the-art infrastructural facility and cutting edge technology, we are engaged in manufacturing and supplying Synchronous Belts. These belts are ideal for contamination sensitive applications. We use optimum quality materials, sourced from trusted vendors to manufacture these belts. Clients can obtain these Synchronous Belts in different thickness and finishing from us.

Features:

- Can withstand high temperature

- No lubrication is required

- Excellent flexibility

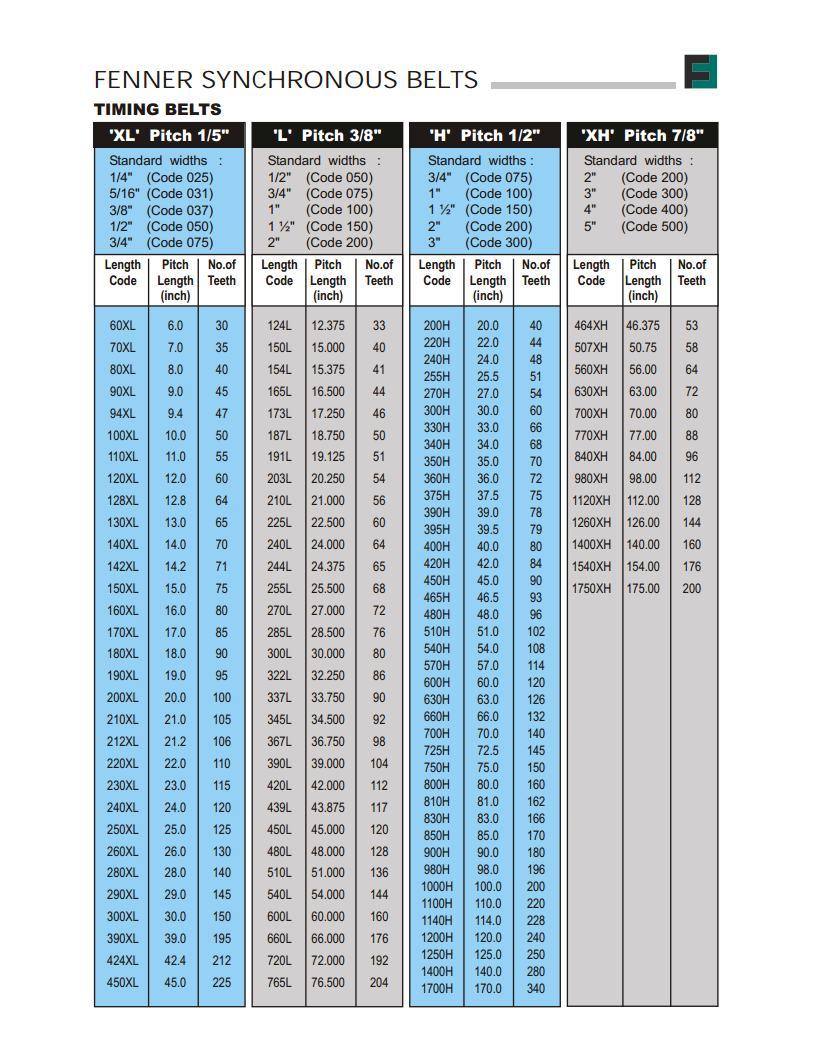

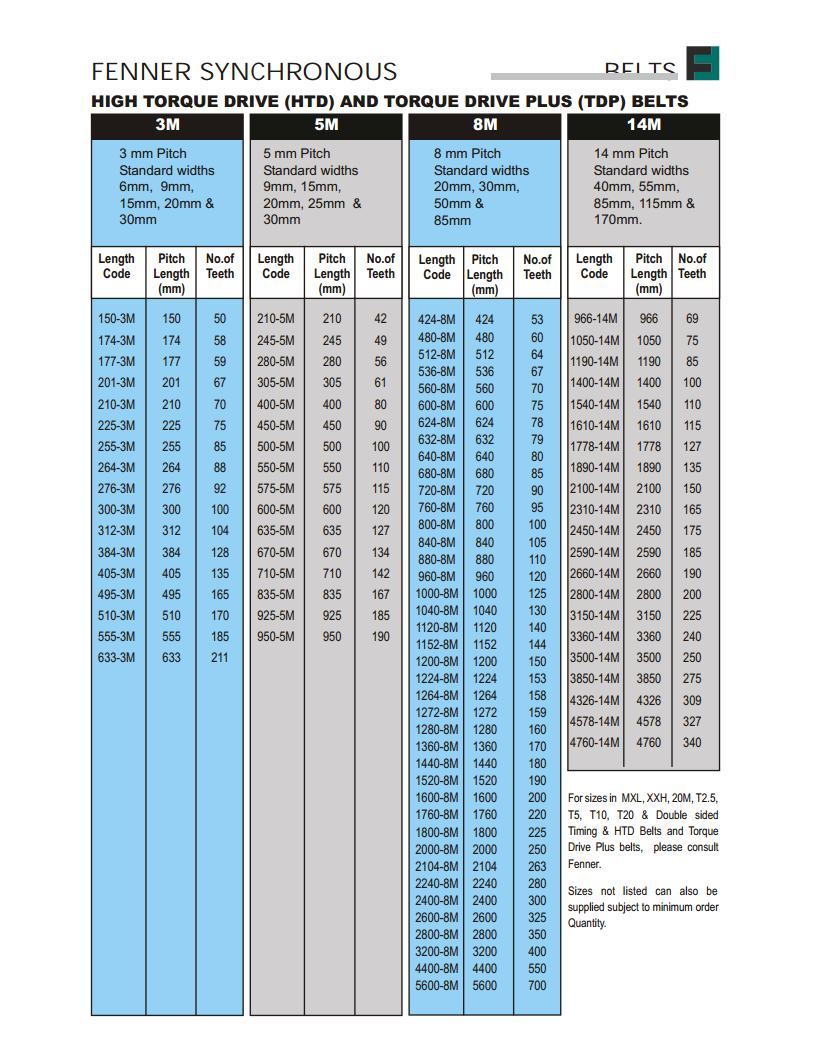

(Fenner Timing belts/ Fenner HTD belts/ Fenner Torque Drive Plus Belts)

- Positive non-slip drive maintains exact speed ratio without creep or slip.

- Minimum heat buildup results in cooler operations.

- These belts do not stretch in use and are corrosion free, clean operation makes them ideal for contamination sensitive applications.

- Moderate oil resistant and electrically conductive according to ISO 9563.

- Can withstand temperatures between -20Deg C to 100 Deg C.

Advantages:

- No maintenance, no lubrication is required. No re-tensioning. No need for adjustable motor bases. Reduced operating cost.

- Wide range of applications from FHP to 500KW, speeds up to 20000 rpm, speed ratio up to 20: 1.

- Compact design with lesser weight. High flexibility allows the use of very small pulleys.

- Positioning accuracy and constant driven speeds with efficiencies up to 99%.

- Smooth operation and constant angular velocity with no jerk or vibration.

- Reduced belt tension. Longer drive bearing life.

- Optimized tooth design providing optimum meshing efficiency, energy loss reduced to an absolute minimum.

- Reduced noise levels.

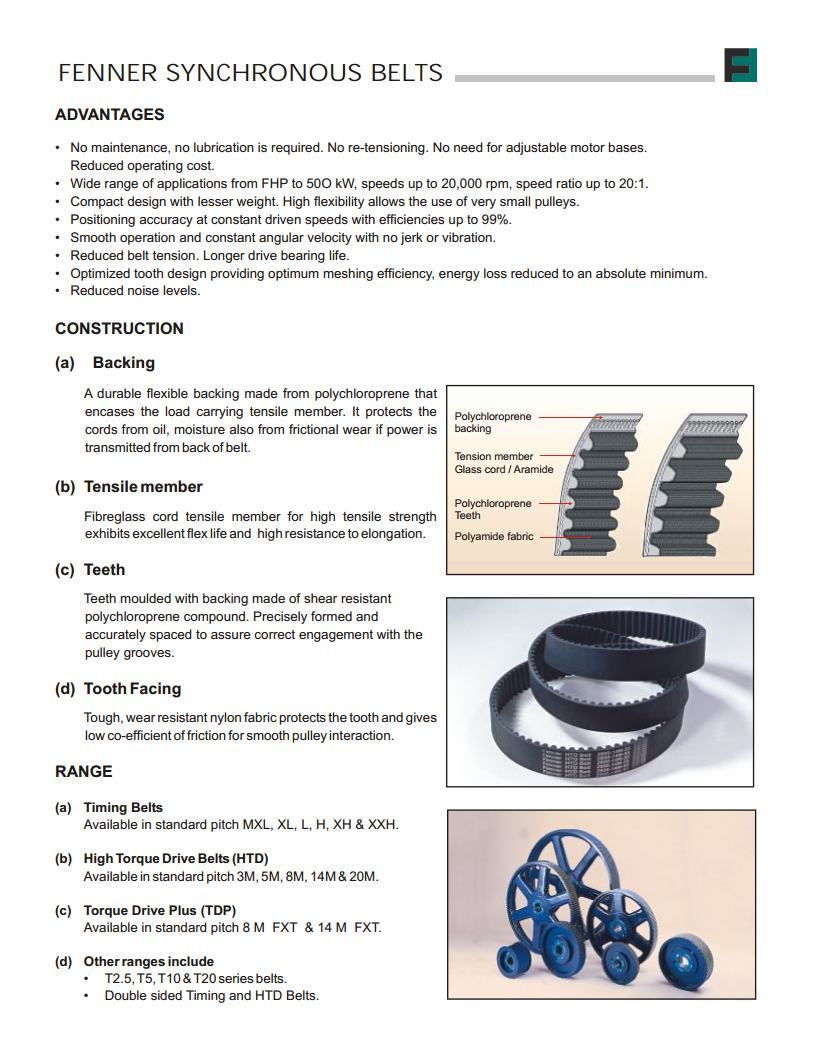

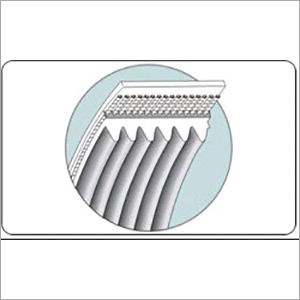

Construction:

- A durable flexible backing made from polychloroprene that encases the load carrying tensile member. It protects the cords from oil, moisture also from frictional wear if power is transmitted from back of belt.

- Fiberglass cord tensile member for high tensile strength exhibits excellent flex life and high resistance to elongation.

- Teeth moulded with backing made of shear resistant polychloroprene compound. Precisely formed and accurately spaced to assure correct engagement with the pulley grooves.

- Tough, wear resistant nylon fabric protects the tooth and gives low co-efficient of friction for smooth pulley interaction.

FAQs of Synchronous Belts:

Q: What material is the Synchronous Belt made of?

A: The Synchronous Belt is made of rubber.Q: Is the Synchronous Belt resistant to oil?

A: Yes, the Synchronous Belt is oil-resistant.Q: What is the width range of the Synchronous Belt?

A: The width of the Synchronous Belt ranges from 10 to 100 millimeters (mm).Q: What type of conveyor structure does the Synchronous Belt feature?

A: The Synchronous Belt has a Flat Belt conveyor structure.Q: What is the main usage of the Synchronous Belt?

A: The Synchronous Belt is primarily used for industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Belts Category

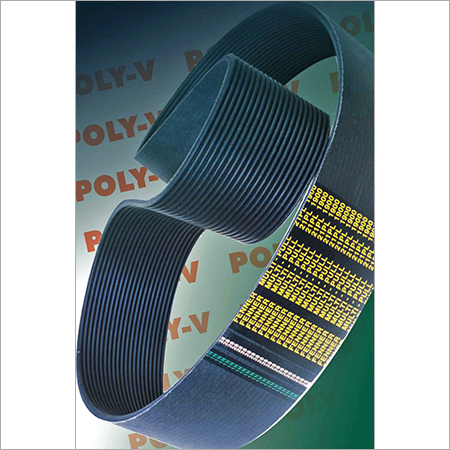

Poly V Belts

Minimum Order Quantity : 10 Meters

Structure : Belt

Material : Rubber

Color : Black

Usage : Industrial

Resistant Feature : Oil Resistant

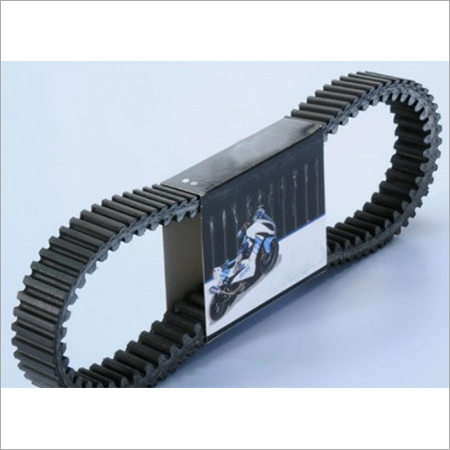

Variator Belts

Minimum Order Quantity : 1 Piece

Structure : Belt

Material : Rubber

Color : Black

Usage : Industrial

Resistant Feature : Oil Resistant

Fenner Industrial Belts

Minimum Order Quantity : 1 Piece

Structure : Belt

Material : Rubber

Color : Black

Usage : Industrial

Resistant Feature : Oil Resistant

Multi Pull Poly V Belts

Minimum Order Quantity : 10 Meters

Structure : Belt

Material : Rubber

Color : White

Usage : Industrial

Resistant Feature : Oil Resistant

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free